Port Labor Showdown: T-Minus 70 Days and Counting

- By [ Jess Dankert , Sarah Gilmore ]

- 07/22/2024

These negotiations are a top issue for retail supply chains this year. Almost six weeks have elapsed since the ILA called off negotiations again, the day before talks were slated to restart on June 11. After ILA President Harold Daggett’s statement two weeks ago, the industry’s hopes for an expeditious resolution become more strained with each passing day of inaction, and despite the USMX’s latest response retailers have grown increasingly concerned that labor disruptions will occur at any or all of the 36 ports lining the U.S. East and Gulf Coasts.

The Latest Developments

The ILA halted negotiations last month with a fiery statement about the purportedly recent discovery of an “auto gate” in use at Maersk’s APM Terminal at the Port of Mobile (and possibly other ports). According to the union, the gate is a violation of automation clauses in the existing master contract—automation is consistently a flashpoint issue for port labor. The ILA is also undoubtedly riding high following its recent win over the South Carolina Ports Authority regarding labor disputes at Charleston’s new Leatherman Terminal, which finally reached an agreement to open last month after sitting largely idle since the spring of 2021 due to the ILA’s lawsuit.

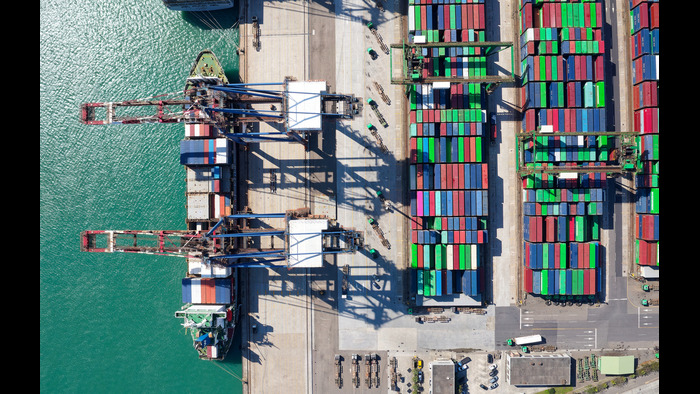

Mr. Daggett has promised that workers will “hit the streets” on October 1 if an agreement has not been reached—a distressing prospect in light of the over 13 million containers of import cargo that pass through East and Gulf Coast ports each year, plus export containers, automobiles, bulk cargo, and more.

The ocean shipping market is already disrupted by the ongoing Red Sea / Suez Canal crisis, soaring spot market rates, Panama Canal restrictions, and more. East and Gulf Coast ports can represent as much as 56% of all U.S.-inbound containers in a given month—the country’s supply chains, and indeed the national economy, can ill afford the impacts of a costly port labor strike.

Retail Persepective & Preparation

Retailers have already developed contingency plans to mitigate the effects of potential labor actions in the Fall—peak shipping season ahead of key U.S. holidays. It may seem early, but retailers are making decisions right now about how to mitigate or avoid the delays and costs of possible East and Gulf Coast port disruptions a few months away. A shipping container may spend as much as two months in transit once it leaves the factory of origin.

Shortly after the ILA’s abrupt cancelation of talks, RILA joined some 160 trade groups in a letter imploring the Biden Administration to help get the ILA and USMX back to the table. However, Mr. Daggett has explicitly said that intervention by the administration and the Department of Labor—or any outside parties—is unwelcome. He and the ILA had previously criticized the administration’s engagement on the West Coast port labor negotiations last year.

Outlook

Few are holding out hope for an easy conclusion to this narrative. East & Gulf Coast negotiations have historically not been as tumultuous as those at West Coast ports, and the ILA hasn’t had a strike since 1977. But getting the parties back to the table is only the current hurdle—reaching an agreement on the master contract is a whole other process. The two sides reportedly remain far apart on key issues, especially technology and wages. These must be resolved as soon as possible and well in advance of the master contract expiration, to ensure that U.S. and global supply chains can continue to function optimally.

Stay tuned—more to come on this subject!

See RILA’s previous post on this topic for additional background.

Tags

-

Public Policy

-

Supply Chain

-

Workforce